From the offset plate to the image on paper

In the world of printing, it is important to understand how high-quality printed materials are created and what role each stage of the production process plays. One of the key components in this process is the offset plate. In this article, we will consider what an offset plate is, how the process of its exposure occurs, and how the image is transferred from the plate to the paper.

What is an offset plate?

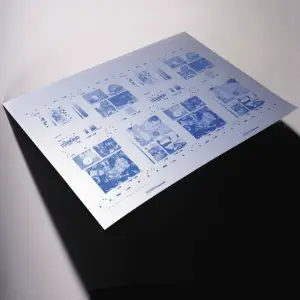

An offset plate is a thin sheet of metal (usually aluminum) or other material on the surface of which there is a light-sensitive layer. This layer is used to transfer the image or text from the computer to the plate and then to the paper in the printing process. Offset plates play a critical role in modern printing, as they ensure high quality and accuracy of prints.

The process of coating offset plates

The process of coating offset plates includes several main stages:

Preparation of the layout. First, a layout of an image or text is created in a graphic editor on a computer. This layout contains all the necessary elements that need to be transferred to the printed material.

Cover plate. After the image layout is ready, it is transferred to the plate with the help of a special exposure machine. Exposure is the process of exposing a plate to light through a negative or positive image. The photosensitive layer on the plate reacts to light, forming an invisible image.

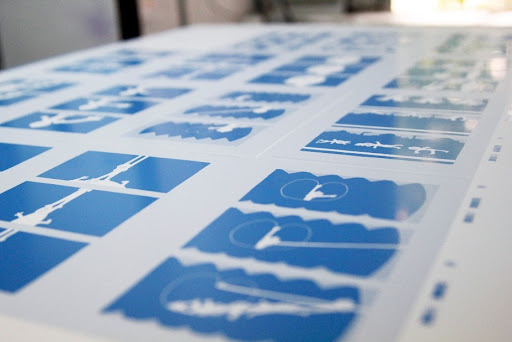

Manifestation of the plate. After exposure, the plate is revealed with the help of chemical reagents. During this process, the image becomes visible and the photosensitive layer that was not exposed to light is washed away. Only the image remains on the plate, ready to be transferred to paper.

Transferring the image from the plate to the paper. Offset printing is an indirect printing method that includes several stages of image transfer:

Transfer to a rubber roller: after developing the image on the plate, it is installed in the printing machine. The offset plate transfers the image to the rubber shaft, which acts as an intermediate medium.

Transfer to paper: A rubber roller coated with paint contacts the paper, transferring the image onto it. This method allows you to achieve high accuracy and quality of printing, since the rubber shaft is more flexible and able to accurately transfer details to different surfaces.

Drying and finishing: after printing the image on the paper, the sheets can undergo additional processing steps, such as drying, varnishing or lamination, which increase their durability and aesthetic appearance.

Advantages of offset printing

Offset printing has several significant advantages:

High quality: provides excellent clarity and detail of images and texts.

Efficiency: Suitable for large runs, making it cost-effective.

Versatility: the ability to print on various materials, including paper, cardboard, self-adhesive and others.

At “Your Printing House” in Ternopil, we use offset printing technology to provide our customers with high-quality products. Our specialists will be happy to help you create any printed materials, from business cards to advertising brochures, with guaranteed quality and a professional approach to every detail.